Ongoing strategic investment in plant and process continue to secure Richply’s success in the plywood industry. Since inception, Richply’s shareholders have applied a philosophy of continually reinvesting resources into our business to modernize and streamline our manufacturing processes, to remain cost-competitive, and to consistently respond to the evolving needs of our customers and markets.

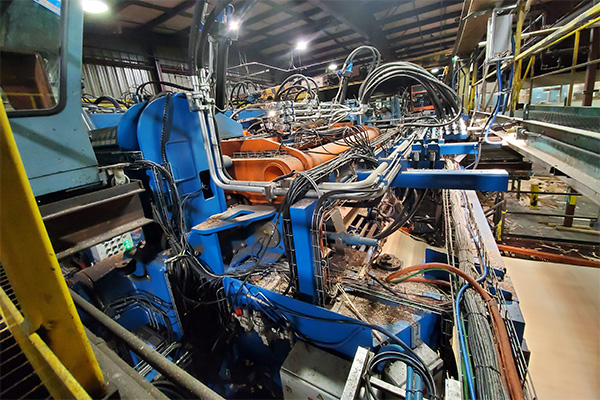

In the past ten years alone, we have made multi-million dollar investments at the green end in the form of a log processing facility, new de-barker, increased log conditioning capacity, and more recently the approval and installation of a new lathe line in response to changes in our fibre diet. Inside the plant, major capital has been spent on a new dryer, new composer, and automated patching. The installation of a new boiler with a three-stage electrostatic precipitator has drastically lowered our mill’s consumption of natural gas, reducing our mill’s carbon footprint, and contributing greatly to improved air quality in the region.

State of the art technology is only part of the equation. Our people are a key to our success. The workforce is highly motivated; since most are owners, they understand it is in their best interest to focus on producing quality value-added products the most efficient way possible in order to earn our customer’s business. And because we are 100% employee owned, staff turnover is low, we don’t have to constantly train new people, and we are not prone to production disruptions from labour disputes. Stability in our labour force allows Richply to be a reliable and consistent supply source for our customers and markets.